Risk based inspection “RBI”

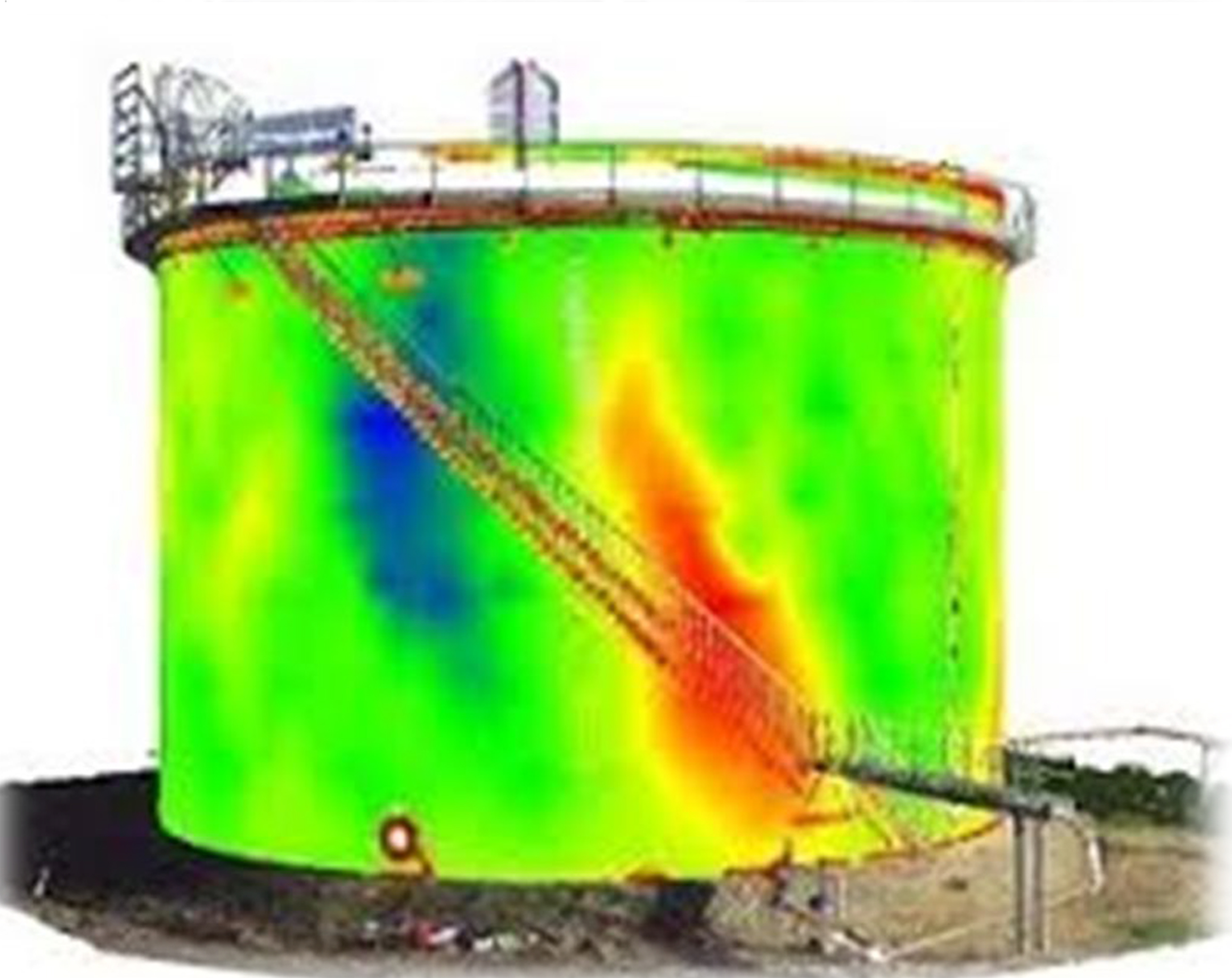

Risk-Based Inspection (RBI) is an asset integrity management methodology that uses the probability of failure (POF) and consequence of failure (COF) to calculate risk for individual assets. The risk and risk drivers identified for each asset are then used to prioritize and drive inspection strategies that define where to focus inspection efforts, which methods are most effective, and when to perform inspections.

In considering the actual condition of the vessel and its current risks of failure, RBI can deliver significant improvements to inspection programs.

These benefits can be:

Extension of intervals of inspection, in some circumstances extending inspection intervals many years beyond those that statutory inspection regimes specify, saving money.

Reduction of the scope of inspections based on expected failure mechanisms.

This can mean significant savings through simply less inspection tasks, through to the entire removal of inspection scopes such as internal inspections. Identifying unforeseen risks, corrosion study during RBI sometimes identify damage mechanisms not considered previously or not ever inspected before.

Our Approach and Services: We follow the principles of standards such as API 580 and API 581 and guided by professional engineers with significant experience in successfully executing RBI programs.

For the successful achievement of the desired outcomes from RBI programs we provide:

- Integrity engineering services to review asset inspection histories and create and optimize inspection and test plans (ITPs) using RBI processes.

- Failure Modes and Effects Analysis to make risk assessments of critical failure modes to which inspection programs can be focused.

Risk-Based Inspection (RBI) is an optimal maintenance approach utilized to inspect industrial equipment like pressure vessels, heat exchangers, and piping. RBI serves as a method for making informed decisions to improve inspection plans.